D-U-N-S Certified

We are the leaders in Machining

and Hard Chrome plating

Machining involves the process of shaping materials using various cutting tools, while hard chrome plating is a technique used to apply a layer of chromium to a surface for improved durability,corrosion resistance, and other beneficial properties.

Capabilities

Capabilities

With machines having a between center distance of 10 meters and job handling capacity of about 25 tonnes, we can manufacture/refurbish almost all shafts requiring this service.

Services

Services

We offer end to end machining services in grinding,honing,turning and milling. We also have an inhouse facility for Hard chrome plating and phosphating. We do refurnishment of old job and make it ready to use.

Extended Services

We provide solution in hard chrome plating of dies,punch,blank holding,cavity and molds. We offer this services for all sizes and weights.

One Stop Solution For Hard Chrome

Plating

Our integrated services encompass both hard chrome plating and phosphating to comprehensively address your metal component needs.Rigorously adhering to stringent quality standards, our hard chrome plating ensures components meet the highest industry requirements. Simultaneously, our vital phosphating services contribute to prolonged performance and lifespan, offering excellent corrosion resistance.

On Time Delivery

On Time Delivery

One Stop Solution for Machining- Turning,Milling,Grinding & Honing

Turning,Milling,Grinding & Honing

At Akshay Organics Pvt.Ltd, We understand the importance of precision in machining. Our highly skilled machinists work with the latest CNC technology to deliver exceptional machining services for even the most complex parts. From milling and turning to drilling,honing,straightning, we have the capabilities to handle any size or volume of projects. Our attention to detail and strict quality control measures ensure that your components are machined to precise specifications

Quality Assurance

Quality Assurance

Quality is at the forefront of everything we do. We meticulously adhere to strict quality control standards throughout the plating process & Machining Process. With comprehensive inspections, precise measurements, and rigorous testing procedures, we guarantee the Machining and plating services.

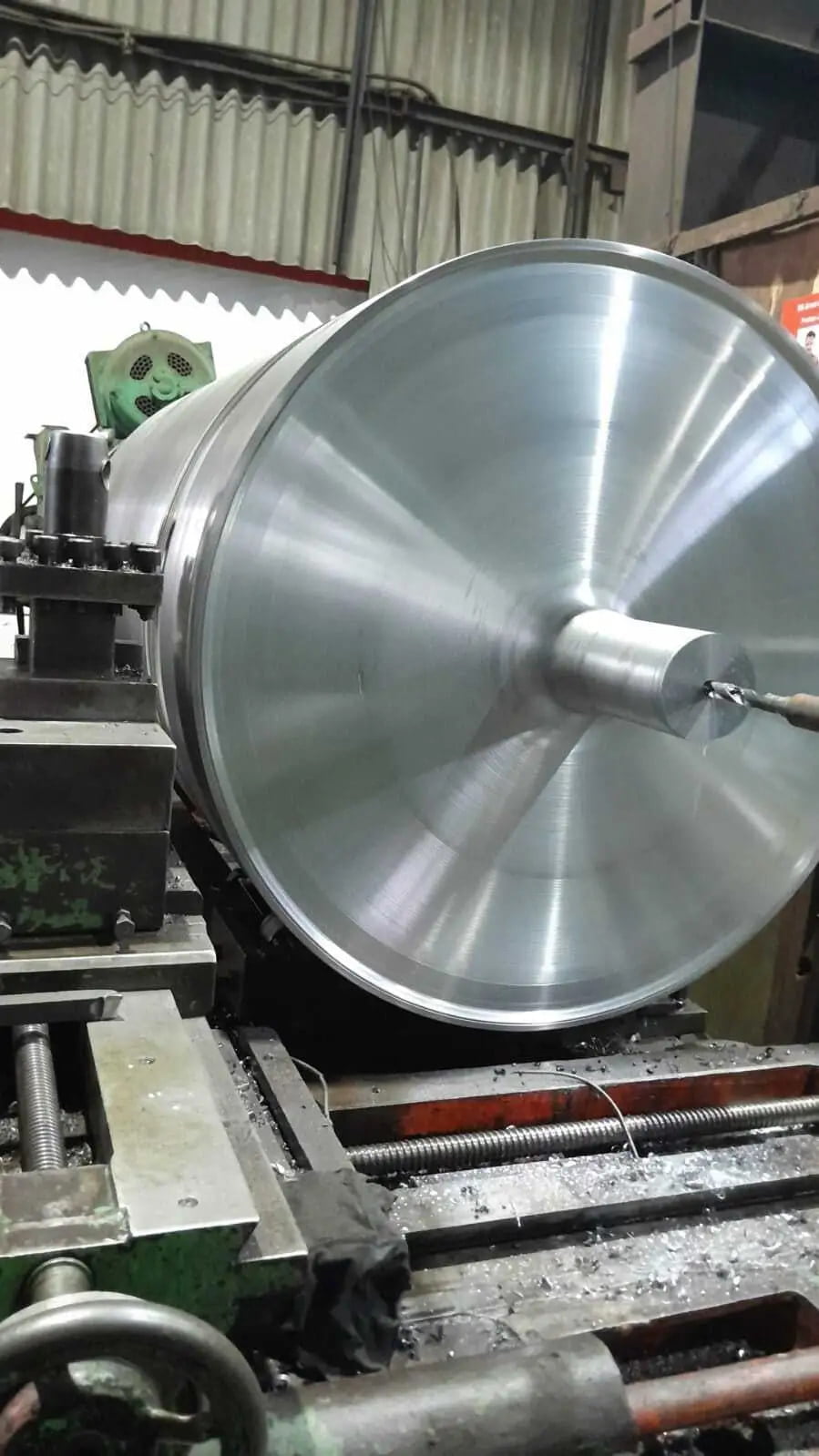

Machining Facility

CNC / Conventional Turning

Our turning services are a hallmark of precision and craftsmanship. With the capacity to handle jobs up to 14 meters in length and 1250 mm in diameter, we expertly shape and refine cylindrical components. Our advanced machinery and skilled team ensure each turn meets the highest industry standards. Whether for manufacturing or repairs, trust us to deliver top-tier turning solutions. Experience precision and quality for your unique requirements.

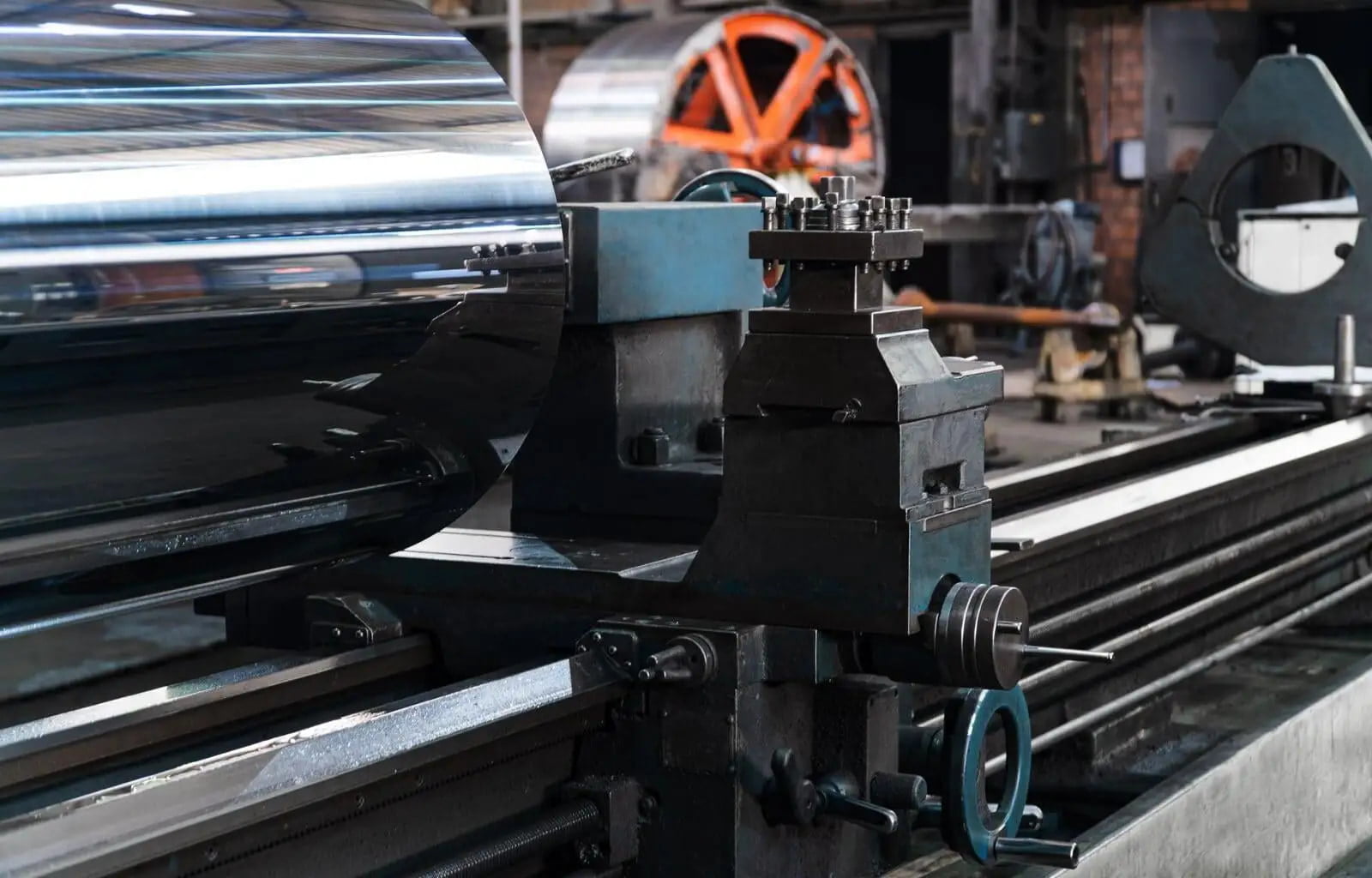

Cylindrical / Roll Grinding

At our facility, precision is paramount, and our cylindrical grinding services are a testament to that commitment. With the capacity to handle grinding jobs up to 10 meters between centers and diameters of up to 2000 mm, we excel in shaping and refining cylindrical components with unparalleled accuracy. Our skilled technicians and state-of-the-art equipment ensure that each grind is executed to perfection, delivering products that meet the highest industry standards. Trust us for exceptional cylindrical grinding solutions tailored to your specific needs.

Honing

Honing

We possess the capability to perform honing on components up to 3 meters in length and 1000 mm in diameter. With state-of-the-art equipment and a highly skilled team, we excel in refining the internal surfaces of cylindrical components to exacting standards. Whether it's achieving tight tolerances, improving surface finish, or enhancing the overall quality of your parts, you can trust us to deliver honing services that meet and exceed industry expectations.

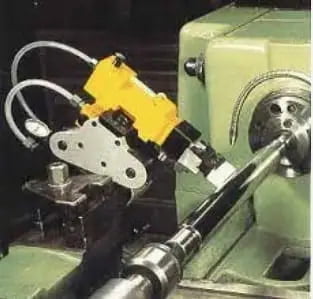

Superfinishing

Our superfinishing services redefine precision. We have the capability to achieve surface roughness levels as low as 0.01 Ra, resulting in a flawless mirror finish. Our specialized techniques and skilled technicians ensure that each component undergoes meticulous superfinishing, enhancing its performance, durability, and aesthetic appeal. Whether it's for aerospace, automotive, or industrial applications, trust us to deliver superfinishing excellence that surpasses industry standards, giving your products the perfect finishing touch

Milling

We utilize our state-of-the-art planomiller, boasting a substantial bed size of 8 meters in length and 1200 mm in width, to expertly shape and refine a wide range of components. With the ability to handle large-scale projects, our skilled technicians ensure that each milling operation meets exacting specifications. Whether it's for intricate detailing or large-scale production, our milling services deliver exceptional results, ensuring the highest quality and precision for your unique requirements.

Bar Straightning

Our commitment to quality extends to every aspect of our services, including our in-house bar straightening facility. Equipped with a powerful 500-tonne straightening machine, we have the capability to straighten cylindrical components with diameters of up to 300 mm and lengths of up to 10 meters. Our precision straightening process ensures that even the most challenging of jobs meet the strictest industry standards. Count on us to provide reliable, high-quality straightening services that optimize the integrity and performance of your components, no matter the complexity.

Baking / De - hydrogen Embrittlement

We prioritize the integrity and longevity of your components. Following our meticulous hard chrome plating process, we offer a critical service known as baking to counteract hydrogen embrittlement. Our specialized furnace, with a length of 3 meters and a width of 600 mm, plays a crucial role in this process. Controlled temperatures and precise conditions ensure that any hydrogen absorbed during plating is effectively removed, reducing the risk of embrittlement and ensuring the structural reliability of your components. Trust us to provide a comprehensive solution that upholds the highest industry standards, safeguarding the quality and performance of your parts

Hard Chrome Plating & Phosphating

Hard Chrome Plating

Hard Chrome Plating

Our hard chrome plating services are unmatched in both scale and quality. With the capability to handle jobs of up to 14 meters in length and weighing up to 25 tonnes, we specialize in providing durable and corrosion-resistant chrome plating solutions. Our state-of-the-art processes and expert team ensure that every component receives a flawless, high-quality finish that meets stringent industry standards. Whether for industrial or precision applications, rely on us for superior hard chrome plating tailored to your specific requirements.

Zinc/Manganese Phophating

Zinc/Manganese Phophating

Our manganese and zinc phosphating facility sets the standard for excellence. With the capability to accommodate components of up to 9 meters in length and a diameter of 600 mm, we specialize in providing superior phosphating solutions. Our advanced processes and skilled team ensure that each component receives a durable and corrosion-resistant phosphate coating. Whether for enhancing surface properties or improving paint adhesion, you can trust us to deliver high-quality manganese and zinc phosphating tailored to your specific needs.

Environmental Responsibility

Solar Panels

Considering contribution of eco managment system, we estabilished our rooftop with solar panal systems.

Extensive Range Of Services

Our hardchrome plating and machining ability to cover a broad spectrum of applications, from enhancing the surface hardness of industrial machinery to repairing and maintaining hydraulic cylinders and other components subjected to intense wear and tear. No matter the size or complexity of the project, we have the expertise and resources to exceed your expectations.

Customized Solutions

We understand that every client's requirements are unique. Our team works closely with you to assess your specific needs and develop tailored solutions that cater to your individual demands. By leveraging our capabilities and expertise, we consistently deliver custom hardchrome platingturning,cylindrical grinding,milling and honing process that meet your desired specifications.

Our Expertise

With last two decades of experience in the industry, our team of highly skilled technicians possesses an in-depth understanding of the hardchrome plating,turning,cylindrical grinding,milling and honing process. We have successfully catered to a wide range of industries, including defence, automotive, manufacturing, and more. Rest assured, your components are in capable hands.

Environmentally Responsible

As responsible members of the industrial sector, we prioritize eco-friendly practices. Our plating and machining processes comply with all environmental regulations and standards. We employ sustainable techniques, minimize waste generation, and promote recycling efforts, ensuring our operations align with a greener future.

Applications of the services we provide

Hydraulic

Cylinder

Hydraulic Piston Rod and Tie-Bars

Hard Chrome Plating of Dies